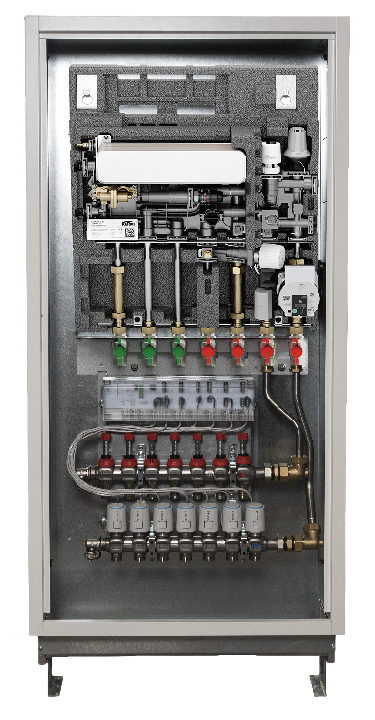

Home station pro for panel heating

With mixed heating circuit

KERMI x-net home stations pro ensure hygienic domestic water heating based on the instantaneous principle and provide an efficient heat supply using an integrated underfloor heating manifold and a direct heating circuit.

Benefits

- Modular design, the right home station for every requirement

- Fitted with top quality components for a long service life

- Summer bypass and differential pressure controller for balancing the stations with each other already included as standard

- The innovative plug connection guarantees a secure connection even if there are pressure surges, and installation and maintenance are simple and tool-free.

- High energy efficiency to minimise heating costs

- Three-part thermal insulation shells reduce heat loss while at the same time preventing cold water being unintentionally heated.

- One of the lightest home stations on the market for quick and easy installation.

- Innovative new material significantly reduces heat dissipation

- and has an extremely smooth surface which prevents deposits and blockages.

- Already meets RoHS 2024 requirements today

- Stainless steel heat exchangers are available in x-net home stations in performance categories 37, 45, 55, and 75 kW.

- Copper or stainless steel brazed heat exchangers are available, depending on the drinking water analysis.

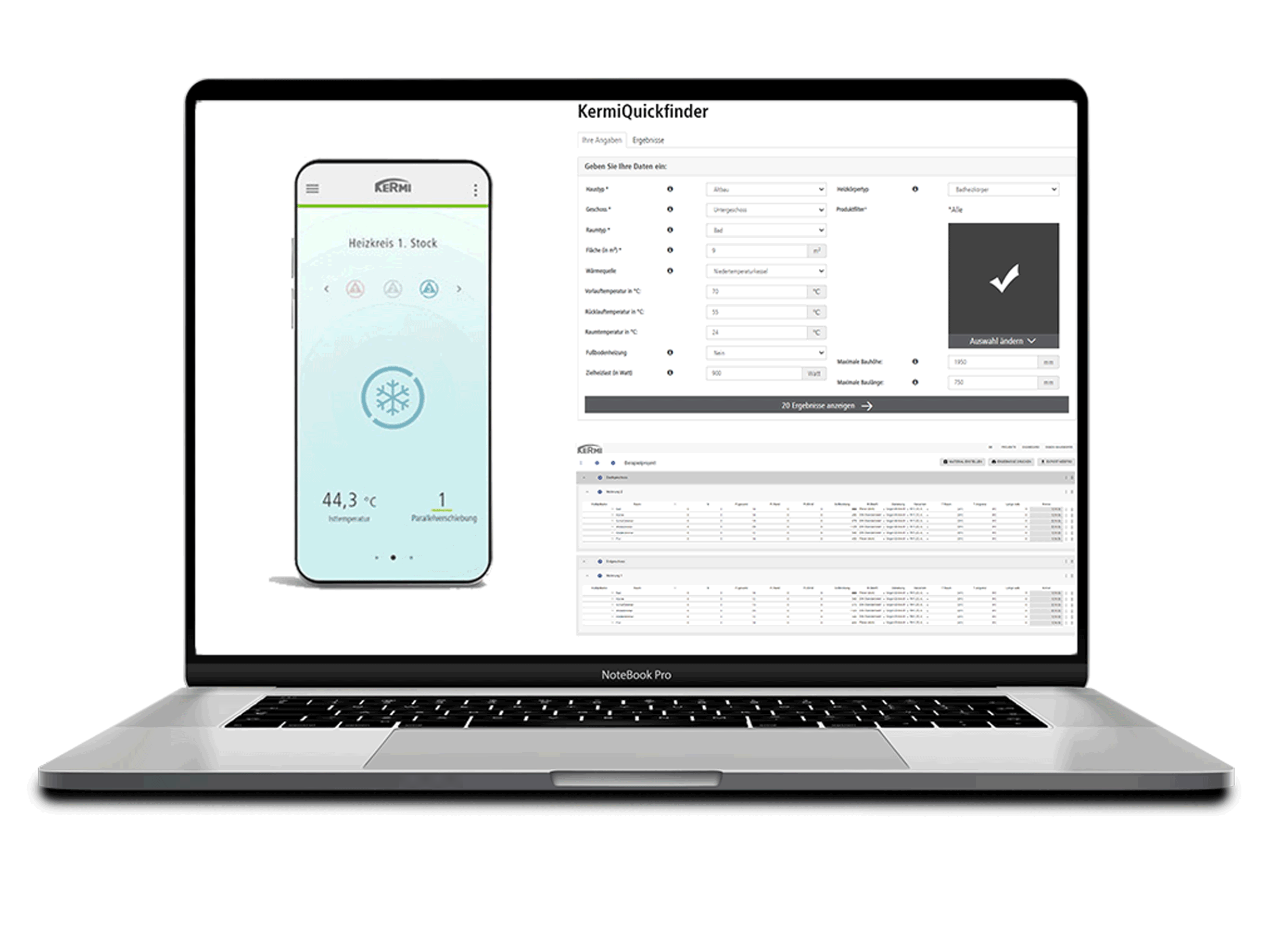

Product information

Application area

Areas of application

- Hot water

- Panel heating

- optional + bathroom radiator

Product description and function

Product description and function

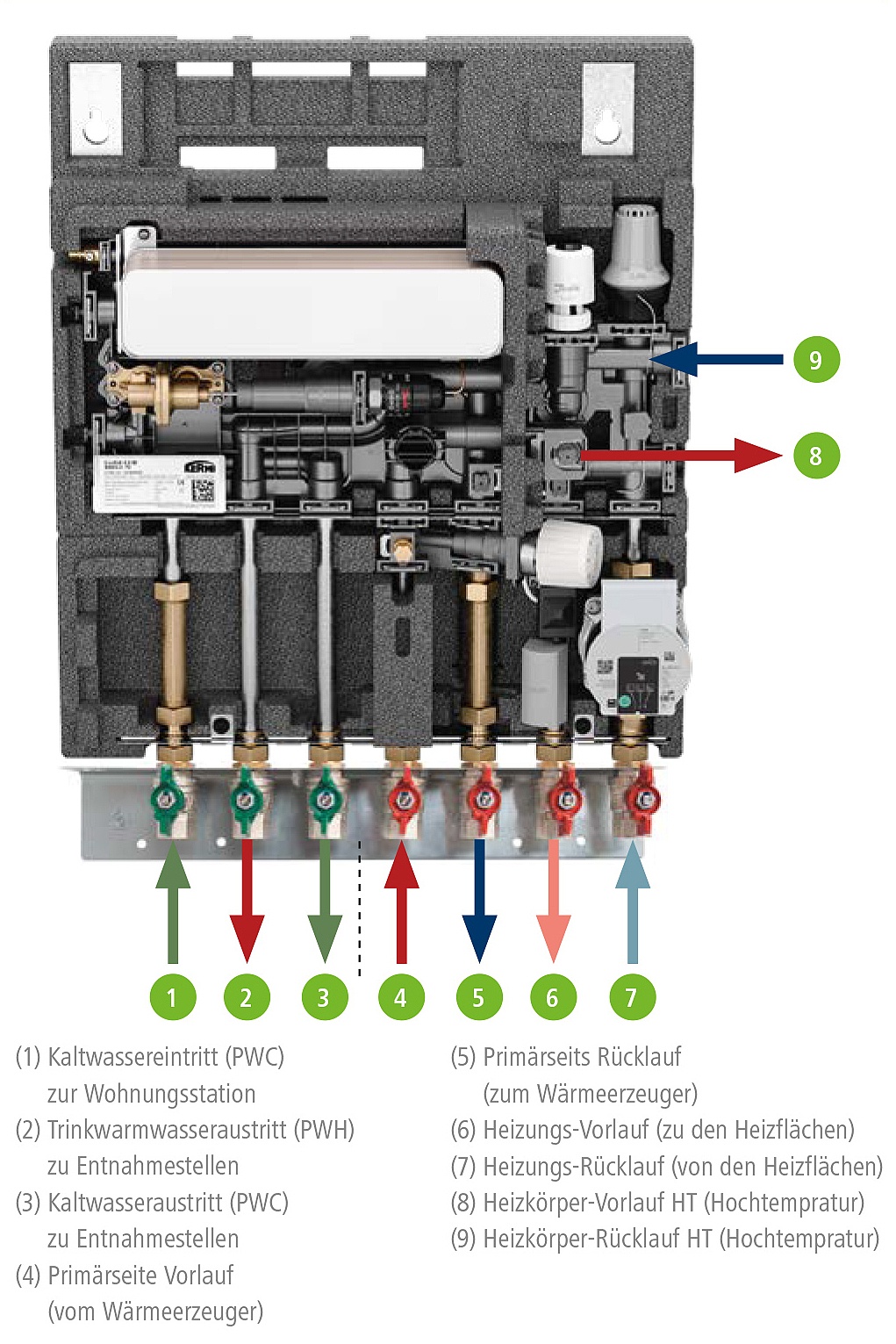

The home station (1) consists of:

- Heat exchanger without gaskets

- Integrated underfloor heating mixing circuit for connecting the x-net distribution sets 2–12 radiators

- 2 differential pressure controllers for high energy efficiency and constant hot water temperature (for balancing several stations with each other)

- Zone valve with actuator and STW for protecting the maximum flow temperature of the mixed heating circuit (55 °C)

- Integrated summer bypass

- Adapters for heat flowmeter and cold water meter

- EPP housing consisting of rear panel with recessed grips to facilitate installation and three-part insulating cover

The primary lines and x-net manifold set (3) are connected using the x-net ball valve set

Depending on requirements, 2 to 12 heating circuits are connected to the heating circuit via the x-net manifold set (3), which supplies the panel heating.

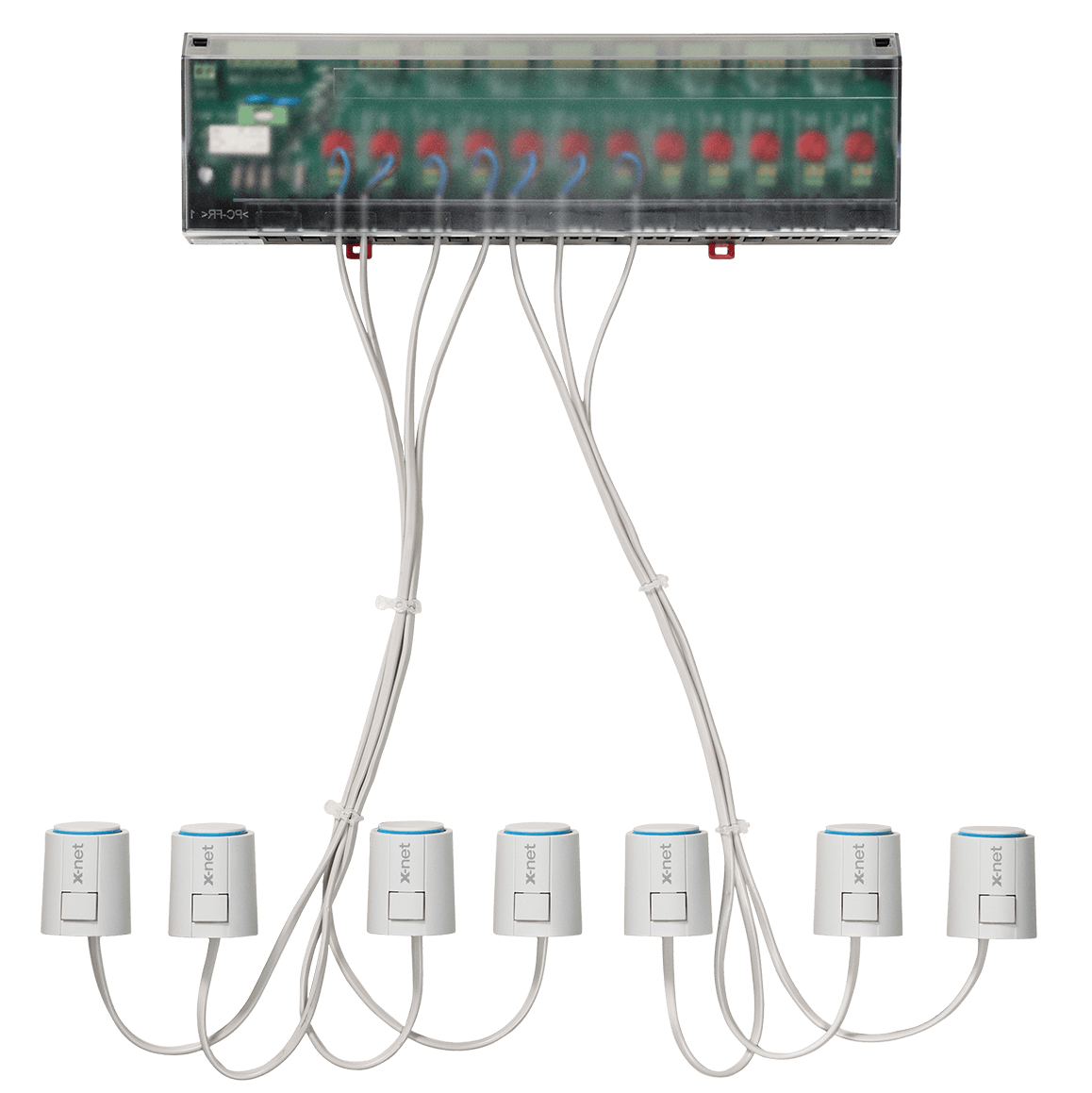

The top-hat rail already included in the x-net manifold set makes it easy to install the x-net terminal strips directly.

Pre-wired terminal strips such as the x-net ready line (4) are also available for this

The voltage is supplied for the heating circuit pump and the safety temperature monitor directly via the terminal strips.

Easy to wire up, no additional junction boxes etc. required.

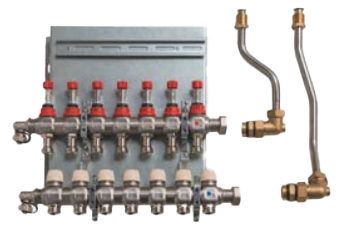

Accessories

Accessories

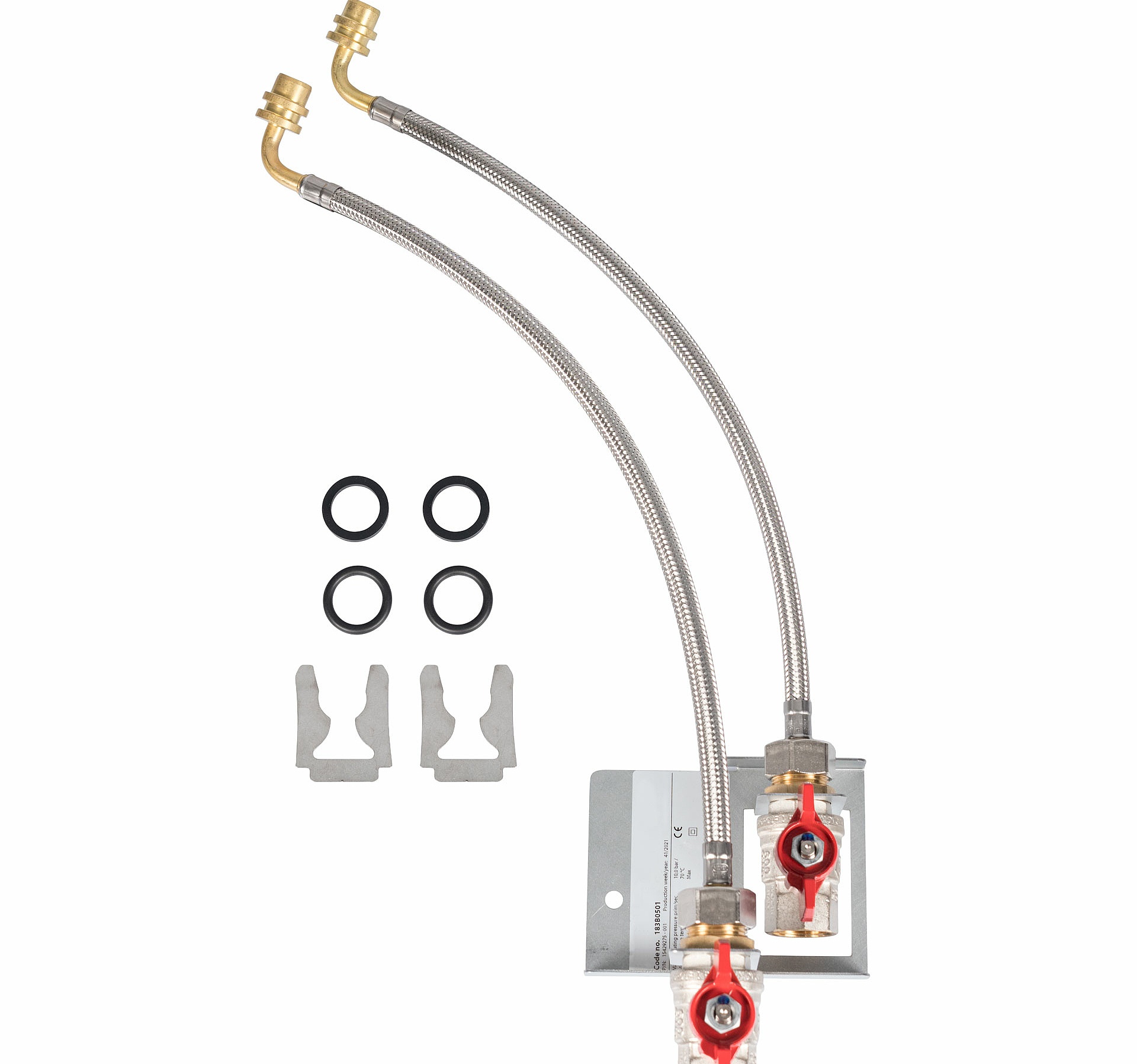

The primary lines and the manifold set are connected via the x-net ball valve set

Depending on requirements, 2 to 12 heating circuits are connected to the mixed heating circuit via the manifold set, which supplies the panel heating.

The top-hat rail already included in the manifold set makes it easy to install the terminal strips directly.

Pre-wired terminal strips such as the x-net ready line are also available for this. The voltage is supplied for the heating circuit pump and the safety temperature monitor directly via the terminal strips.

Easy to wire up, no additional junction boxes etc. required

Connections

Connections

Cabinets

Cabinets

Various flush-mounted cabinets are available for installing the x-net home stations – depending on the home station / area of application and the accessories used.

Body and cover large size 1–4:

Height 1365 mm, width 610–930 mm.

Suitable for home station with mixed

heating circuit and directly connected panel heating manifold

Body and cover small size 5:

Height 910 mm, width 690 mm.

Suitable for home stations with unmixed

heating circuit or without panel heating manifold directly connected

Optional accessories

Radiator set Pro

Circulation set pro